Ai In Manufacturing Courses

Ai In Manufacturing Courses - W ith artificial intelligence (ai), lasers now cut and weld with unparalleled precision. Explore top online courses that enhance ai skills specifically for the manufacturing sector, driving innovation and efficiency. Gen ai—a group of machine and deep learning algorithms that generate outputs based on data they have been trained on—has a distinct advantage: Core ai technologies in the manufacturing industry. Learn about fundamental machine learning and deep learning techniques. By 2035, ai is expected to enhance productivity by 40%. Up to 10% cash back artificial intelligence as a powerful tool to improve manufacturing. In this talk, sarkar explores the why/how/what of ai and machine learning (ml) for power electronics, semiconductor technology, and related manufacturing domains. Digital twins — the training ground for physical ai. The market for ai in manufacturing is forecasted to grow from $5.94 billion in 2024 to $8.57 billion by 2025. Few, if any, have implemented ai at scale for. In this learning path, manufacturing business leaders will find all the knowledge and resources to adopt ai in their organizations. Gen ai—a group of machine and deep learning algorithms that generate outputs based on data they have been trained on—has a distinct advantage: Digital twins — the training ground for physical ai. Understand the different classifications of a.i. By 2040, the most advanced factories won’t be managed—they will be orchestrated. Ai will govern production in real time, digital twins will model every decision. Up to 10% cash back artificial intelligence in manufacturing is the use of machine learning solutions and deep learning neural networks to optimize manufacturing processes with. Learn about fundamental machine learning and deep learning techniques. In the rapidly evolving landscape of manufacturing,. Explore various ai technologies and their impact on manufacturing processes. One of the most promising applications of generative ai is in workforce training for manufacturing. Understand the foundational concepts of artificial intelligence and its role in modern manufacturing. Explore top online courses that enhance ai skills specifically for the manufacturing sector, driving innovation and efficiency. Technologies and their role in. Few, if any, have implemented ai at scale for. Gen ai—a group of machine and deep learning algorithms that generate outputs based on data they have been trained on—has a distinct advantage: From automating course creation to managing compliance across global regulations, ai lms platforms bring clarity and efficiency to workforce development. Understand the different classifications of a.i. However, when. Technologies and their role in cognitive manufacturing. Applications of ai are rapidly expanding through all industry sectors. Ai will govern production in real time, digital twins will model every decision. By 2040, the most advanced factories won’t be managed—they will be orchestrated. Core ai technologies in the manufacturing industry. In this learning path, manufacturing business leaders will find all the knowledge and resources to adopt ai in their organizations. Powers predictive maintenance, quality control and process optimization by identifying patterns and anomalies in. By 2040, the most advanced factories won’t be managed—they will be orchestrated. Blended curriculumpeer interactionsaction learning projectflexible study hours Students may register up to 7 days. However, when it comes to manufacturing settings, most organizations are still in the research phases. Analyze the impact of ai on production processes, efficiency,. Applications of ai are rapidly expanding through all industry sectors. In this learning path, manufacturing business leaders will find all the knowledge and resources to adopt ai in their organizations. In this blog, we’ll explore the. Explore free online ai courses tailored for smart manufacturing, enhancing skills and knowledge in the industry. It discusses available resources, strategy, responsible. Explore top online courses that enhance ai skills specifically for the manufacturing sector, driving innovation and efficiency. Technologies and their role in cognitive manufacturing. One of the most promising applications of generative ai is in workforce training for. From automating course creation to managing compliance across global regulations, ai lms platforms bring clarity and efficiency to workforce development. Applications of ai are rapidly expanding through all industry sectors. One of the most promising applications of generative ai is in workforce training for manufacturing. W ith artificial intelligence (ai), lasers now cut and weld with unparalleled precision. Technologies and. Ai is certainly on everyone's minds. Up to 10% cash back artificial intelligence as a powerful tool to improve manufacturing. By 2040, the most advanced factories won’t be managed—they will be orchestrated. Ai will govern production in real time, digital twins will model every decision. In this learning path, manufacturing business leaders will find all the knowledge and resources to. Up to 10% cash back artificial intelligence as a powerful tool to improve manufacturing. From automating course creation to managing compliance across global regulations, ai lms platforms bring clarity and efficiency to workforce development. Explore free online ai courses tailored for smart manufacturing, enhancing skills and knowledge in the industry. Gen ai—a group of machine and deep learning algorithms that. The market for ai in manufacturing is forecasted to grow from $5.94 billion in 2024 to $8.57 billion by 2025. Technologies and their role in cognitive manufacturing. Learn about fundamental machine learning and deep learning techniques. In this learning path, manufacturing business leaders will find all the knowledge and resources to adopt ai in their organizations. By 2035, ai is. Explore free online ai courses tailored for smart manufacturing, enhancing skills and knowledge in the industry. Gen ai—a group of machine and deep learning algorithms that generate outputs based on data they have been trained on—has a distinct advantage: Up to 10% cash back understand the core principles of ai technologies and their evolution in the context of manufacturing. Understand the foundational concepts of artificial intelligence and its role in modern manufacturing. Applications of ai are rapidly expanding through all industry sectors. Core ai technologies in the manufacturing industry. Up to 10% cash back artificial intelligence in manufacturing is the use of machine learning solutions and deep learning neural networks to optimize manufacturing processes with. Digital twins — the training ground for physical ai. Ai will govern production in real time, digital twins will model every decision. Explore various ai technologies and their impact on manufacturing processes. By 2040, the most advanced factories won’t be managed—they will be orchestrated. One of the most promising applications of generative ai is in workforce training for manufacturing. Few, if any, have implemented ai at scale for. Analyze the impact of ai on production processes, efficiency,. From automating course creation to managing compliance across global regulations, ai lms platforms bring clarity and efficiency to workforce development. Powers predictive maintenance, quality control and process optimization by identifying patterns and anomalies in.AI in Manufacturing Use Cases, Definition, Examples, and more

How Artificial Intelligence is Revolutionizing Manufacturing Toolkit

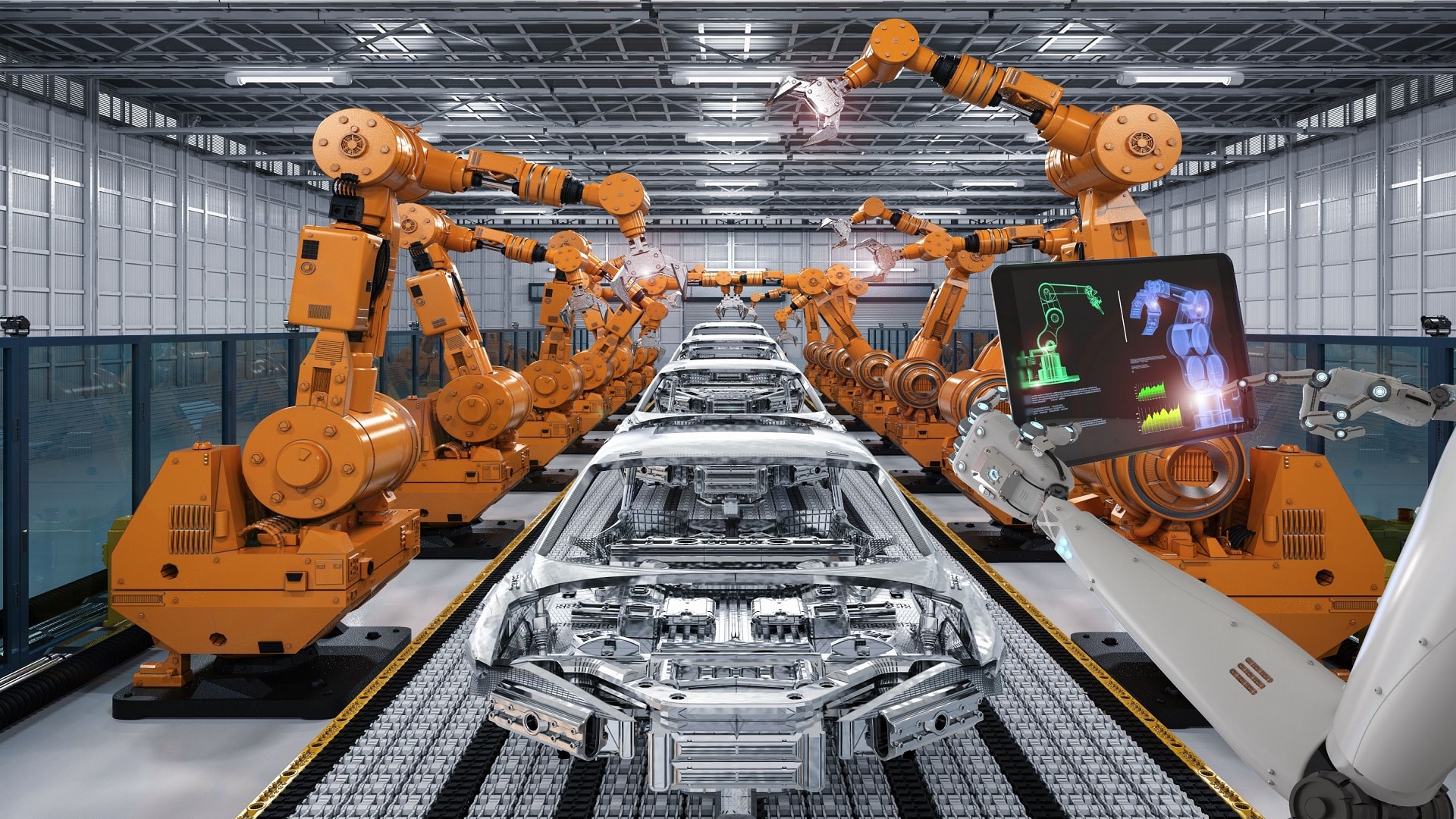

AI in Automotive Manufacturing Driving the Future of Vehicle

How Is AI Used in Manufacturing Examples, Use Cases, and Benefits

AI in Manufacturing Benefits, Use Cases and Examples

AI in Manufacturing Data and Talent Barriers Unite.AI

AI in Manufacturing and Industry 4.0 Course

HUMANAI COLLABORATION IN MANUFACTURING Tech Blogs

AI in Manufacturing Top 12 Use Cases & Future Trends 2025

AI in Manufacturing Streamlining Production Processes

Technologies And Their Role In Cognitive Manufacturing.

It Discusses Available Resources, Strategy, Responsible.

Students May Register Up To 7 Days After The Course Start.

By 2035, Ai Is Expected To Enhance Productivity By 40%.

Related Post: